Machining Low- and Medium-Carbon Steel Alloys

Cut these common and useful steels efficiently with chip breaking solutions

Low-carbon and medium-carbon steels form the backbone of virtually every shop’s operations in their general engineering applications and fabricated parts.

What defines them is the percentage of carbon in the steel; 0.15 to 0.30 percent for low-carbon “mild” steel and 0.30 to 0.60 percent for medium-carbon steel. According to cnccookbook.com, mild steels are common with broad uses because of their good machinability and weldability combined with low cost. Most grades are available cold formed or hot rolled. Mild steel is used for parts that may be case hardened, but whose core strength is not critical. Given the material’s favorable cost, manufacturers often use it for high-volume parts such as screw machine parts, shafts, lightly stressed gears, and hard-wearing surfaces, pins, and chains. Other applications include weldments, gear boxes, drivetrains, and general engineering parts.

However, mild steels present problems for turning, drilling and milling. They are soft and gummy materials, frequently forming long, problematic chips. It’s no surprise that the most frequently asked question about processing these steels is how to break the chip. Answers are found in chip control through feed rate, depth of cut, and selection of insert geometry.

Medium-carbon steel has balanced ductility and strength as well as good wear resistance for large parts, forgings and automotive components. Medium-carbon steels are stronger and harder than low-carbon steel, but they are more difficult to form, weld and cut.

Marriage of Machining and Application

In a discussion, Dave Zunis, director of service and applications engineering, Absolute Machine Tools, Lorain, Ohio; Craig Adorni, applications engineer, Absolute Machine Tools; and Rich Ford, senior sales engineer/MTI for Kennametal Inc., Pittsburgh, outlined approaches to selecting the right cutting tool and cutting data to meet the challenges of machining low-carbon steel. Information about the right cutting tool, insert geometry, machining speeds and feeds for the application are on-line at Kennametal’s Engineering Calculator or its NOVO proprietary cutting tool database.

Adorni pointed to obvious problems with hole drilling and chip breaking. “When you are drilling a hole and the chips start to come up on the tool and toolholder, you can’t have that ball of chips in the way, so you need to make sure you break the chip.”

There is a definite impact on automation if chips aren’t broken, according to Zunis. “If the drill or the tap leaves a bunch of chips, they can get in the way of, let’s say, a robot grabbing the part,” he said. “The best milling applications will produce a chip that is like popcorn, like a little six or a little nine that you can actually hold in your hand. It will be like tiny chips like popcorn flying all over; they’re not connected to each other and don’t act like a long string.

“But in the case of low-carbon steels you can end up with a chip that is like an eagle’s nest, getting wrapped around the drill and thrown everywhere,” he continued. He noted that, typically, an air blast can’t move the chips out of the way—breaking the chips is required. This can be done by increasing feed rates or changing the geometry of the insert so the chip comes off in a small piece “basically exploding the chips,” he said.

Running at a higher feed rate seems attractive. “But customers are often afraid to run the newer machines at the proper feed rate because they are ‘old school’ and used to running the machines too slow, and this typically creates the long chip,” said Adorni. “But if you can increase that feed rate … you have a tendency to break the chip. Some machinists don’t take into account the newer technology of the CNCs, inserts and tooling, which are made so that when you get to a certain feed rate the tool was designed or developed for, you can break or snap the chip. But if you can’t get there and you don’t use the geometry of the tool like you are supposed to, then you will get a big, long chip, causing problems in the toolchanger.”

New Carbide Grade Launched

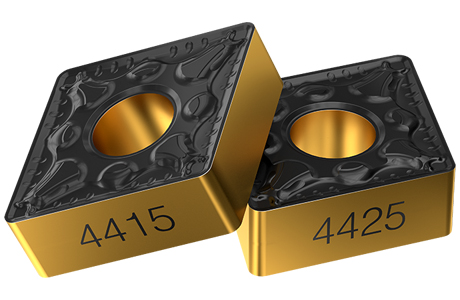

New cutting tool technology offers a better way to approach these steel grades, according to Sandvik Coromant, Fair Lawn, N.J. It has launched a new carbide grade—GC4415/GC4425 with a second-generation Inveo coating. The new grade, available with both ISO-shaped and proprietary pocket inserts, is suitable for turning low-alloyed and unalloyed steels in mass and batch production.

“The new grades are new in every way,” said Keith Brake, turning specialist for Sandvik Coromant. “We have improved the coating, substrate and our post-treatment process. These improvements have given us a reliable and efficient process for steel turning applications, as the grades perform well in both roughing and finishing applications, showing a 25 percent tool life increase. The new substrate also allows GC4425 to perform well in interrupted cutting applications where other P25 inserts may struggle. All these things add up to better performance and tool life for our customers.”

In all machining applications, having a controlled chip is vital, according to Brake. This can be especially difficult in softer, gummier materials like mild steel. “An uncontrolled chip can lead to premature insert failure, scrapped parts or, worst of all, an injured employee. Sandvik Coromant has a variety of chip breaking geometries with the ‘LC’ coming to mind first for this type of application. This chip breaker, combined with proper cut data, can yield terrific results.

“For customers looking to increase their productivity, we have released the new grades in our CoroTurn Prime family as well,” he continued. “PrimeTurning is not a new technology, but we have noticed dramatic improvements in tool life and consistency with the new steel turning grades, most notably the 4425 CoroTurn Prime ‘B’ inserts. Roughing cycle reductions of 30 percent are not uncommon with CoroTurn Prime.” He also said the CoroTurn Prime has an ability to create radii and square shoulders without any secondary tooling.

Sandvik Coromant has documented case studies for its GC4425/GC4415 inserts “in many steel turning applications in many different materials and the grade has just been released,” said Brake. “The automotive and general engineering sectors can make wonderful use of the new grades, but these grades are not limited to only those areas. If you are turning steel, GC4415 and GC4425 will provide improvements.”

Chip Formers, Surface Treatment

Another issue with the gumminess of low-carbon steel is its tendency to create built-up edges (BUE) on tools. Iscar USA, Arlington, Texas, uses several different approaches to deal with this, according to Randy Hudgins, national product manager–turning and threading. Iscar’s Sumo Tec surface treatment smooths the top of the insert, allowing material to glide across the insert more easily, preventing BUE. In addition, Iscar has recently developed a selection of new chip formers for steel machining ranging from heavy cuts to finishing cuts.

“An important aid for our customers is the nomenclature for our chip formers,” said Hudgins. “It enables end users to easily identify and select the right chip former. For example, let’s take a dash M3P chip former. The first letter M indicates the medium application, the 3 indicates standard medium feed rate, and the P at the end designates the material (steel). Iscar goes all the way down to the F1P, with F for finishing, 1 for low feed rate and, again, P for steel.”

Chip control is critical in high-volume production industries such as automotive, which uses low-carbon steel for parts like transmission shafts, steering shafts and, well, shafts of all kinds. Why? The automotive industry depends on using a lot of robotics and can’t afford to shut down production while chips are cleaned out of machines. That’s especially true where there is long, continuous turning, according to Hudgins.

“We encounter a variety of production machines for turning low-carbon steel parts, including multiple-spindle, twin-spindle, and multifunction machines as well as Swiss-style and CNC automatic lathes,” he said.

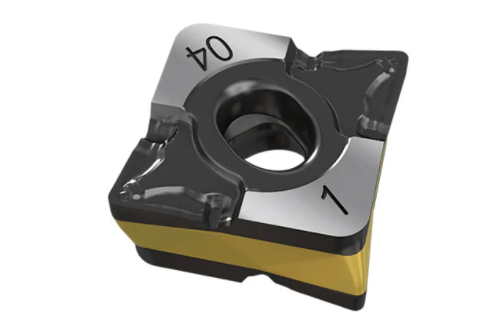

As an alternative to conventional ISO turning inserts, Iscar introduced the CXMG Logiq4Turn product line, which doubles the cutting edges on positive rake inserts intended for general turning applications. “It’s an economical solution for 80° turning and provides double-sided, positive four cutting edge inserts that easily replace the positive two cutting edge inserts. The dovetail shape fits into a unique pocket design, assuring better insert positioning and stability to guarantee longer insert tool life,” said Hudgins. “The holders are available with or without through-tool coolant channels.”

In addition, the new double-sided CXMG inserts operate similarly to CCMT positive inserts and can replace standard CCMT inserts. In some applications, such as long shafts, CXMG’s positive geometry relieves a lot of pressure and still has strength, and because of the dovetail geometry can also replace standard negative CNMG inserts.

Challenges in Drilling and Boring

When it comes to holemaking processes like drilling and boring, low-carbon steel is challenging because of its gumminess, agreed Jack Burley, vice president of sales and engineering for BIG Kaiser Precision Tooling Inc., Hoffman Estates, Illinois. “From my point of view, many companies feel that low-carbon steels are easy to machine, based on the success they have with holemaking tools, typically the drills and boring tools they buy from us. [However,] low-carbon steel’s low tensile strength requires several things in the tool geometry to be successful in drilling and boring. For drilling depth, you really should have coolant-through directed precisely into the cut with enough pressure to break chips,” said Burley.

For deep-hole drilling, coolant is especially important, such as in vertical deep-hole drilling where it’s imperative that chips are evacuated. “What I mean by deep-hole drilling is four times the hole diameter,” said Zunis from Absolute Machine Tools. “Typically, three times and less is considered normal, but if you are going to go 4×, 5× or 6× the chip diameter, you need to get the chip out of the hole. It’s advantageous to use high-pressure coolant while you’re drilling but without enough feed rate, even the coolant isn’t going to help you break the chip. Feed rates, depth of cut, and using the proper insert and toolholder are the main catalysts for breaking the chip.”

BIG Kaiser offers different types of drills, including carbide drills, spade drills and indexable drills, according to Burley. “In the case of indexable drills, however, the amount of feed that you need to break a chip is so high that it might exceed the capacity of the equipment,” he added.

This is also true for holemaking in weldments for agricultural and construction equipment and machinery frames, where low-carbon steel is commonly used. “The metal isn’t usually very pure the way it comes out of foundries, so you’re dealing with a lot of pieces in the material that can be troublesome to machining,” said Burley. “In these areas, it’s double trouble because when you look at fabricated parts, you are putting holes into large, thin-walled workpieces that don’t have a lot structure behind them. As you start pushing on the weldment or frame, it gives a little and springs back and that’s pretty hard on a drill or a boring tool, especially when roughing. What we have done over the years is look at different ways that these kinds of parts and holes can be processed, including circular milling for especially large holes.”

Boring is a bit of a different story, according to Burley. As holes get larger for fabricated weldments, instead of using a drill, shops will burn out the holes and not have to drill them, and instead use a twin cutter to bore the hole using square inserts and twin bores with balanced cutting. Burn-out holes are tough on tools and machines, but with the right tool, proper feeds and speeds, and the right insert, shops can be very effective with the application.

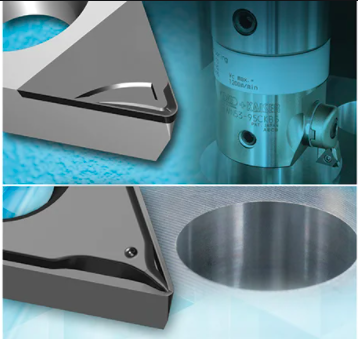

“Fine boring poses its own special challenges,” he said. “When you get a depth of cut of less than 0.020″ [0.508 mm,] the chip is almost impossible to break and it will begin to wrap itself around the tool like a shoe string, causing a lot of trouble with surface finish and with the tool’s ability to bore a hole accurately. As you try to use different speeds and feeds and apply coolant, you end up going with higher feed rates and heavier depths of cut—all of the things that combine to work against producing higher surface finishes and tighter tolerances.”

Last year, BIG Kaiser introduced what it calls unique chip breakers for fine boring low-carbon steel. “These inserts are available with our ELM geometry down to 0.008″ [0.2032 mm] nose radius,” said Burley. “The chip breaker has been pressed into the insert so that we can tightly coil the chip. Even with a shallow DOC, less than 0.010″ [0.254 mm], we can still coil that chip up pretty good, making the chips less troublesome to evacuate from the hole.”

Article Source : www.sme.org

Previous Post

Previous Post Next Post

Next Post